GH3044 nickel-based superalloy GH44

GH3044 (GH44) nickel-based superalloy overview

GH3044 is a solid solution strengthened nickel-based oxidation-resistant alloy. It has high plasticity and moderate heat strength below 900 ℃, and has excellent oxidation resistance and good stamping and welding process performance. It is suitable for manufacturing for long-term work below 900 ℃ Parts of the main combustion chamber and afterburner of the aero engine, as well as the heat shield and guide blades.

GH3044 (GH44) nickel-based superalloy chemical composition

|

C |

Cr |

Ni |

Ti |

Mo |

Al |

W |

Fe |

Mn |

Si |

P |

S |

|

≤ 0.10 |

23.50 26.50 |

Margin |

0.30 0.70 |

≤ 1.50 |

≤ 0.50 |

13.00 16.00 |

≤ 4.00 |

≤ 0.50 |

≤ 0.80 |

≤ 0.013 |

≤ 0.013 |

GH3044 (GH44) nickel-based superalloy similar grades

GH3044 GH44 (China), ЗИ686 ХН60ВТ ВЖ98 (Russia)

GH3044 (GH44) nickel-based superalloy heat treatment system

The solution treatment temperature of hot-rolled and cold-rolled sheets and strips in the supply state is 1120 ~ 1160 ℃, air-cooled, and the material performance is checked in the supply state.

GH3044 (GH44) nickel-based superalloy variety specifications and supply status

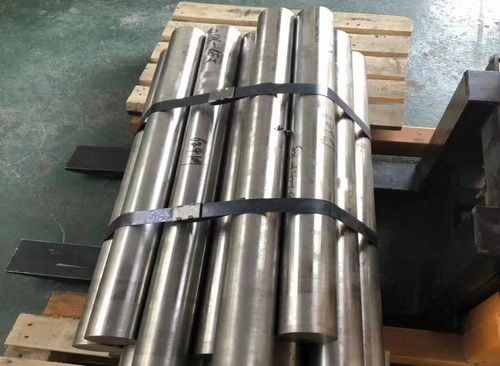

It can supply δ4 ~ 14mm hot rolled plate, δ0.5 ~ 4mm cold rolled plate, δ0.1 ~ 0.8mm strip, diameter d0.3 ~ 10mm, d20 ~ 300mm bar and various diameter ring. Plates and strips are supplied after solid solution, pickling and trimming; wire materials are supplied in cold drawn, solution pickling or semi-hard state, and bars and forgings are supplied without heat treatment.

GH3044 (GH44) nickel-based superalloy melting and casting process

The alloy is melted by electric arc furnace, non-vacuum induction furnace or vacuum induction furnace + electroslag remelting or vacuum arc remelting process.

GH3044 (GH44) nickel-based superalloy application profile and special requirements

It is used to manufacture the components of main combustion chamber and afterburner of aeroengine, long-term working below 950 ~ 1100 ℃, heat shield, cooling blade shell, tube and other parts.

Shenzhen Zhengjie Metal Material Co., Ltd.

Contact person: Mr. Huang (13480167607)

Sales Hotline: 0755-81718772

Q Q: 2263040115 305084123

Website: www.szzj168.com

Email: 2263040115@qq.com

Address: No. 8, Songzi Park, Minzhi, Longhua New District,Shenzhen