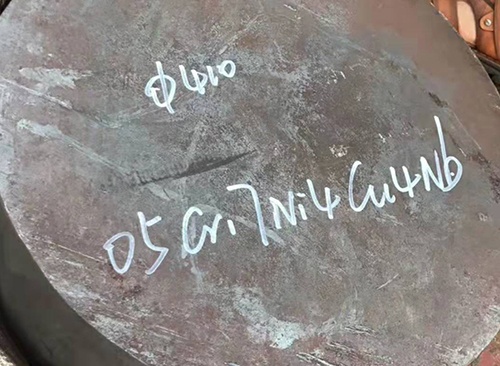

0cr17ni4cu4nb (17-4PH, W.Nr. 1.4542) precipitation hardening steel overview:

0cr17ni4cu4nb alloy is a precipitation, hardened, martensitic stainless steel composed of copper and niobium / rhenium. This grade has properties such as high strength, hardness (up to 300º C / 572º F), and corrosion resistance. After heat treatment, the mechanical properties of the product are more complete, and it can reach compressive strength of up to 1100-1300 mpa (160-190 ksi). This grade cannot be used above 300º C (572º F) or very low temperature. It has good corrosion resistance to the atmosphere and diluted acids or salts. It has the same corrosion resistance as 304 and 430. The performance characteristics of 0cr17ni4cu4nb are easy to adjust the strength level, which can be adjusted by changing the heat treatment process. Martensitic transformation and aging treatment to form a precipitation hardening phase are its main strengthening methods.

0cr17ni4cu4nb (17-4PH, W.Nr. 1.4542) Chemical composition of precipitation hardened steel:

|

C≤ |

Si≤ |

Mn≤ |

P≤ |

S≤ |

Ni |

Cr |

Cu |

Nb+Ta |

|

0.07 |

1.00 |

1.00 |

0.04 |

0.030 |

3.00 5.00 |

15.50 17.50 |

3.00 5.00 |

0.15 0.45 |

0cr17ni4cu4nb (17-4PH, W.Nr. 1.4542) precipitation hardening steel mechanical properties:

Tensile strength σb (MPa): aging at 480 ℃, ≥1310; aging at 550 ℃, ≥1060; aging at 580 ℃, ≥1000; aging at 620 ℃, ≥930

Conditional yield strength σ0.2 (MPa): aging at 480 ° C, ≥1180; aging at 550 ° C, ≥1000; aging at 580 ° C, ≥865; aging at 620 ° C, ≥725

Elongation δ5 (%): aging at 480 ℃, ≥10; aging at 550 ℃, ≥12; aging at 580 ℃, ≥13; aging at 620 ℃, ≥16

Section shrinkage ψ (%): aging at 480 ℃, ≥40; aging at 550 ℃, ≥45; aging at 580 ℃, ≥45; aging at 620 ℃, ≥50

Hardness: solid solution ≤363HB and ≤38HRC; aging at 480 ℃, ≥375HB and ≥40HRC; aging at 550 ℃, ≥331HB and ≥35HRC; aging at 580 ℃, ≥302HB and ≥31HRC; aging at 620 ℃, ≥277HB and ≥28HRC

Density: 7.80g / cm3

0cr17ni4cu4nb (17-4PH, W.Nr. 1.4542) Application field of precipitation hardening steel:

· Offshore platforms, helicopter decks, other platforms

· food industry

· Pulp and paper industry

Aerospace (turbine blades)

· machinery parts

· Nuclear waste barrel

0cr17ni4cu4nb (17-4PH, W.Nr. 1.4542) Specification for Heat Treatment of Precipitation Hardened Steel:

1) Solid cooling at 1020 ~ 1060 ℃

2) Aging at 480 ℃, after solution treatment, air cooling at 470 ~ 490 ℃

3) Aging at 550 ℃, after solution treatment, air cooling at 540 ~ 560 ℃

4) Ageing at 580 ℃, after solution treatment, air cooling at 570 ~ 590 ℃

5) Aging at 620 ℃, after solution treatment, air cooling at 610 ~ 630 ℃.

Shenzhen Zhengjie Metal Material Co., Ltd.

Contact person: Mr. Huang (13480167607)

Sales Hotline: 0755-81718772

Q Q: 2263040115 305084123

Website: www.szzj168.com

Email: 2263040115@qq.com

Address: No. 8, Songzi Park, Minzhi, Longhua New District,Shenzhen