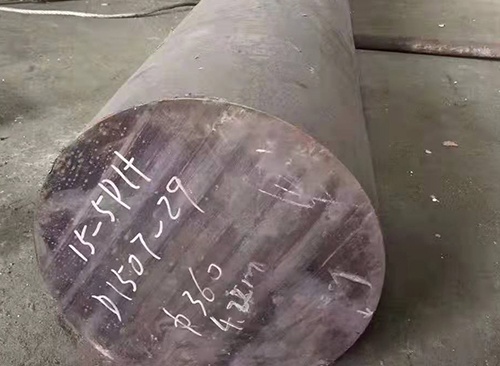

15-5PH (S15500, XM-12, 0Cr15Ni5Cu3Nb) precipitation hardening steel overview:

15-5PH is a martensitic precipitation hardening stainless steel with high strength, high hardness and excellent corrosion resistance, very good transverse toughness and ductility, and high forgeability. The processing performance of 15-5PH is similar to other precipitation hardened stainless steels. Low temperature heat treatment can achieve aging hardening in one step. This material is used for parts that require high transverse strength and toughness, such as valve parts, joints, fasteners, shafts, gears, chemical processing equipment, paper mill equipment, aircraft parts and nuclear reactor parts. In the environment below 593 ° C, 15-5PH shows excellent antioxidant ability. Prolonged exposure to elevated temperatures will reduce the toughness of precipitation-hardened stainless steels. Providing an aging temperature can sometimes reduce this reduction in toughness. If the maximum temperature is at least 28 ° C lower than the aging temperature, the material can be exposed to this high temperature for a short time.

15-5PH (S15500, XM-12, 0Cr15Ni5Cu3Nb) precipitation hardening steel chemical composition:

|

C≤ |

Mn≤ |

Si≤ |

Ni |

Cr |

P≤ |

S≤ |

Cu |

Nb+Ta |

|

0.07 |

1.00 |

1.00 |

3.50 5.50 |

14.00 15.50 |

0.04 |

0.03 |

2.50 4.50 |

0.15 0.45 |

15-5PH (S15500, XM-12, 0Cr15Ni5Cu3Nb) precipitation hardening steel applications:

Used in mechanical parts and marine industry, aerospace, aircraft parts. Components in high pressure corrosive environments: such as valves, shafts, fasteners, connections and gears, etc.

15-5PH (S15500, XM-12, 0Cr15Ni5Cu3Nb) precipitation hardening steel welding:

15-5PH can be shielded and resistance welded. Oxyacetylene welding is not recommended because carbon build-up occurs during welding. If fillers are required, AWS E / ER630 fillers can be used to match weld and matrix properties. Solder joint designs should avoid areas of stress concentration, such as sharp corners, threads, and semi-penetrating solder joints. If the strength requirements of the welded parts are not high, standard austenitic stainless steel fillers can be used, such as E / ER308L. Welding is usually performed in the solid solution state. If welding stress is expected to be high, H1150 can be used for welding. Preheating before welding is generally not required to prevent cracking. Solid solution materials can be directly aging treated to obtain the required strength after welding. However, the best corrosion resistance can only be achieved after the solution has been solid-solved and aged. If the welding is in an excessively aging state, it must be solid solution and then aging after welding.

Shenzhen Zhengjie Metal Material Co., Ltd.

Contact person: Mr. Huang (13480167607)

Sales Hotline: 0755-81718772

Q Q: 2263040115 305084123

Website: www.szzj168.com

Email: 2263040115@qq.com

Address: No. 8, Songzi Park, Minzhi, Longhua New District,Shenzhen